8000 Series

ADT 8020 is a high-efficiency, high performance and low cost fully automatic twin spindle system with up to 12" workpiece size

Applications:

-

Silicon wafers

-

Silicon Carbide

-

Glass

-

Glass on Silicon (sensors)

-

SAW Filters

-

MEMS

-

LED & LED Packages

-

Package Singulation (BGA, QFN, LTCC)

Features and Benefits:

-

Flexibility - Supports Hub and Hubless blades up to 3" O.D.

-

Spindles of 1.8 kW or 2.2 kW high power (for challenging applications)

-

Intuitive operation interface using a large 17" touch screen monitor

Heading 6

Advantages:

-

Highest Dicing Process Speeds - Lowest Cost

-

Air Spindle

-

Fast automatic alignment and cut positioning for increased throughput

-

Automatic Kerf check and quality analysis for maximum precision

-

Process data logging and statistical analysis

-

Fast & Simple Blade Change with a locking spindle shaft

-

SECS/GEM platform ready

-

Full access to any area of the system for easy maintenance access

7120 & 7130 Series

2" and 4" Spindle Dicing Systems

Applications:

-

Ceramic Substrates

-

Thick-film Devices

-

Glass

-

Glass on Silicon (sensors)

-

PZT

-

SAW Filters

-

MEMS

-

LED & LED Packages

-

Package Singulation (BGA, QFN, LTCC)

-

Opto-electronic Components

-

IC Wafers

Features and Options:

-

Extra large area dicing (7100 XLA)

-

Large area

-

Tilting Spindle

-

Dressing Station for diamonds exposure and clogging prevention

Heading 6

Advantages:

-

Full range of automatic vision capabilities

-

Advanced hardware platform for high reliability and low maintenance

-

Heavy Duty, cast-iron base structure for superior precision and accuracy

-

Increased yield, throughput and process control

-

Unique multi-panel processing capabilities

-

Special blade wear forecast algorithm

-

User-friendly software platform

7220 Series

Fully Automatic Dicing Systems

With new architecture and advanced process control tools, the 7200 models deliver substantially higher productivity compared to existing dicing systems, while minimizing the cost of operation.

Applications:

-

Silicon

-

Glass on silicon

-

MEMS

-

GaAs wafers

-

Package Singulation (BGA & QFN)

-

LTCC

-

PCB

-

Hard materials

The 7200 Series is offered in three configurations optimized for IC applications, package singulation or hard material applications.

Advantages:

-

Full range of automatic vision capabilities

-

Advanced hardware platform for high reliability and low maintenance

-

Heavy Duty, cast-iron base structure for superior precision and accuracy

-

Increased yield, throughput and process control

-

Unique multi-panel processing capabilities

-

Special blade wear forecast algorithm

-

User-friendly software platform

PERIPHERAL EQUIPMENT

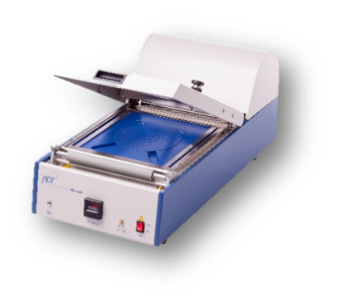

Wafer Cleaner

ADT Model 977 Wafer Cleaner is designed for cleaning workpieces after dicing. It is equipped with a spinning chuck table and a rotating washing/drying arm. The arm can be configured with an atomizing cleaning nozzle or a high pressure nozzle to cope with a wide range of cleanliness requirements

CO2 Bubbler

ADT 947 CO2 Bubbler Inline Injector (CO2 Bubbler) is designed to eliminate particle adhesion and device damage caused by electrostatic effects. T he units dissolve CO2 gas into de-ionized water (DI) used for dicing or cleaning process, thus performing consistent control over an optimal level of resistivity.

DICING BLADES

Resin Bond Dicing Blades

• Resin as binder allows for blade wear management rendering Resin-bond Blades an excellent choice for hard and brittle materials such as: QFN/MLF, Thick Ceramic Substrates, HTCC and Glass

• Resin Blade thickness varies from 3 mil to 100 mil (depending on diamond grit size)

• Diamond grit size ranges from 3 microns to 250 microns (depending on blade thickness)

Metal Sintered Dicing Blades

With slower wear rate than Resin but faster than Nickel, Metal-bond (Sintered) blades are best suited for retaining package shape and size in applications such as:

• BGA

• Soft Alumina

• TiC

• LTCC

• Ferrite

Blade thickness varies from 3 mil to 60 mil (depending on diamond grit size)

Diamond grit size ranges from 2 microns to 70 microns (depending on blade thickness)

Nickel Bond Dicing Blades

• The Nickel binder provides longer blade life and lower wear rate and together with the abrasive makes Nickel-bond Blades a perfect choice for soft material applications such as: PCB, Silicon and BGA

• Blade thickness varies from 0.8 mil to 20 mil (depending on diamond grit size)

• Diamond grit size ranges from 2-4 microns to 70 microns (depending on blade thickness)